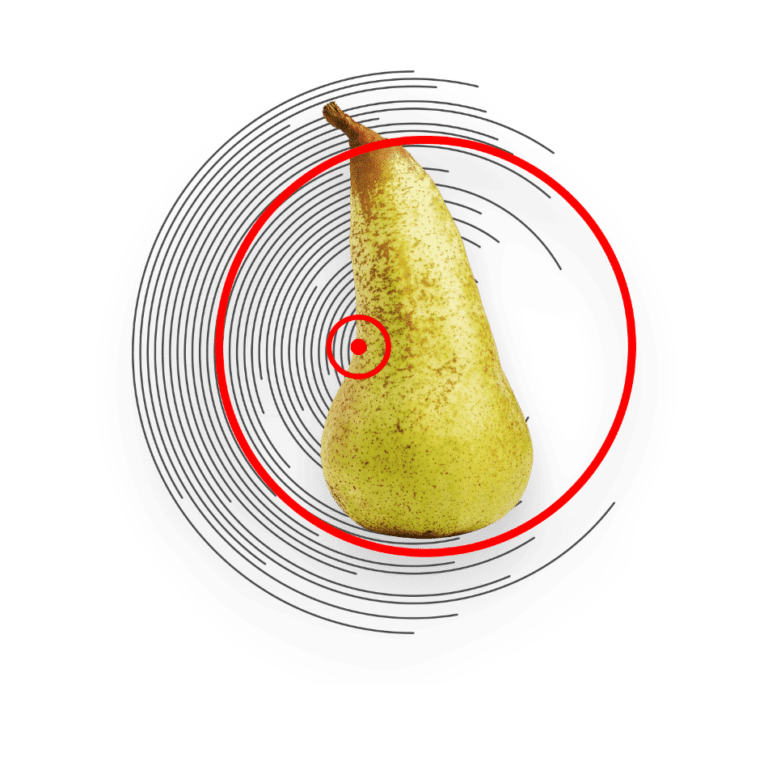

One of the most important steps to keep the fruit intact, both internally and externally. It comes into play immediately after the special “V” belts dedicated to the pear, just before the analysis of the sorting machine. The rotation system we have created avoids the risk of damaging the fruit. Thus, when it comes to examining the grading machine, the analysis work on defects is truly efficient.

You can count on innovative solutions that protect the quality of the fruit from the beginning to the end of the manufacturing process.

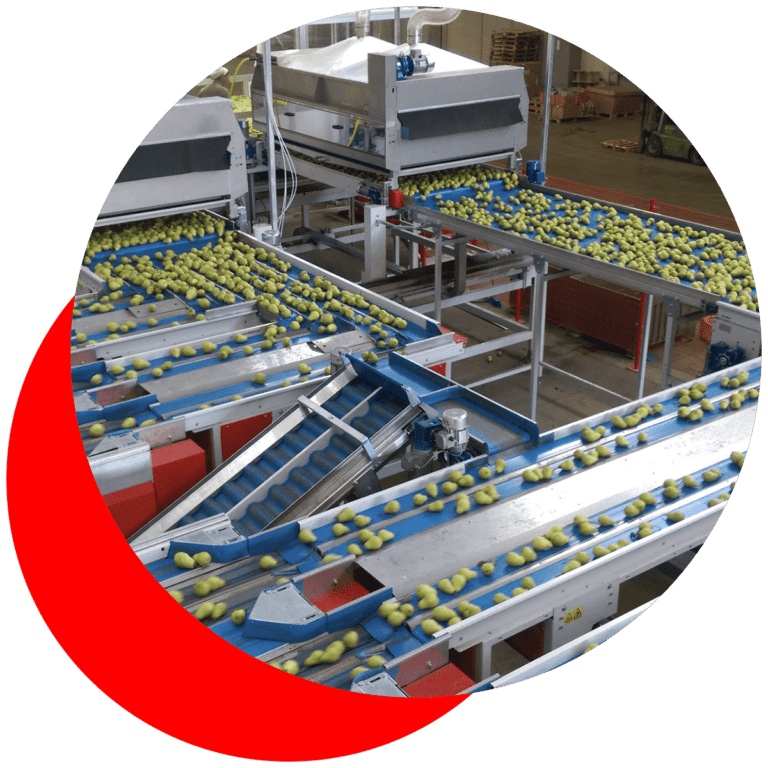

Videos and shots that tell Ser.mac from every perspective.

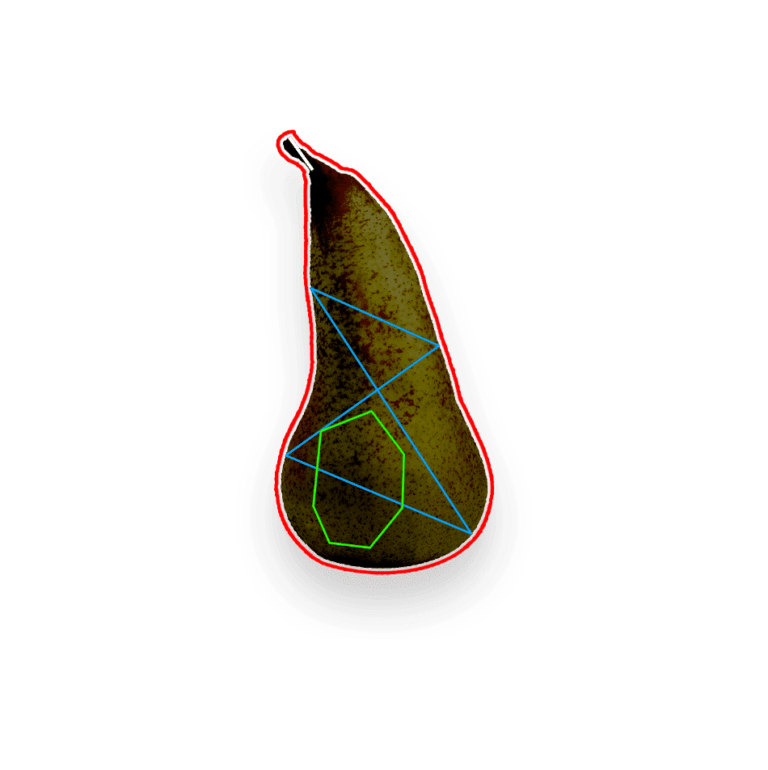

The pear grader has artificial intelligence on its side. The algorithm manages to classify everything necessary and select the best fruits, identifying defects related to colour, weight, diameter, internal and external quality.

The artificial intelligence of the pear grader is able to work down to the smallest details on the parameters of the defects that we want to identify for each fruit, from the color to the percentage of internal and external qualities.