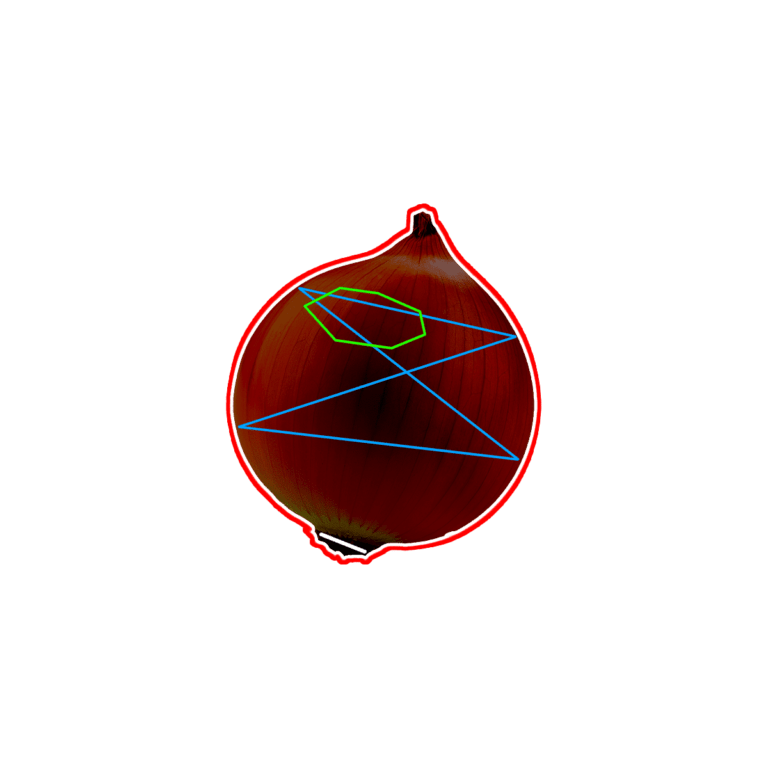

The HDiA sorting machine algorithm even reaches the smallest defects in onions, with mould stains, impurities and peeling. This is how a perfect product is obtained for your market.

The technological solutions of the plants take care of every passage. When the onions reach the end, they are packed and ready for large scale distribution. In the knowledge you are offering a high quality product.

Videos and shots that tell Ser.mac from every perspective.

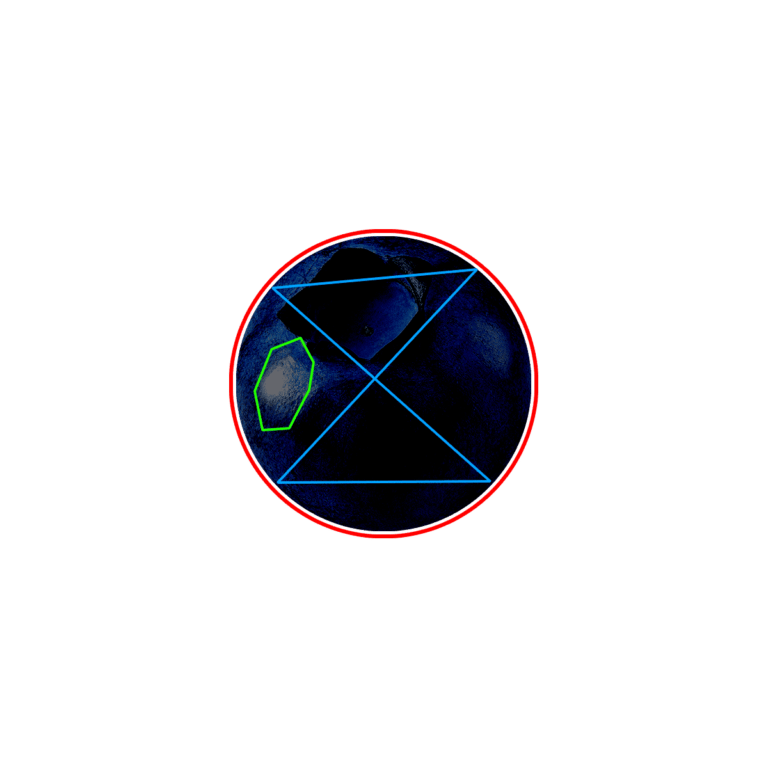

The onion sorting machine uses artificial intelligence which, through an algorithm, manages to grade the defective areas linked to colour, weight, diameter of the onion, internal and external quality.

The artificial intelligence of the sorting machine manages to work in minute detail based on the parameters of the defect you want to identify in this vegetable, from the external colour to the percentage of internal and external quality.